History

Locations

We operate in 4 production plants located in the Veneto region.

The Monselice facilities are dedicated to administrative operations and mechanical processing departments.

The Ceregnano (Rovigo) facilities, structured as an industrial hub, house various strategic departments essential for the verticalised process.

CEREGNANO

(ROVIGO)

Via Trieste, 906

45010 Ceregnano (RO)

Italy

MONSELICE

(PADOVA)

Via Umbria 19 – 20 – 22

Via Emilia 29

35043 Monselice (PD)

Italy

Research

and development

Reducing costs, optimising resources, enhancing quality.

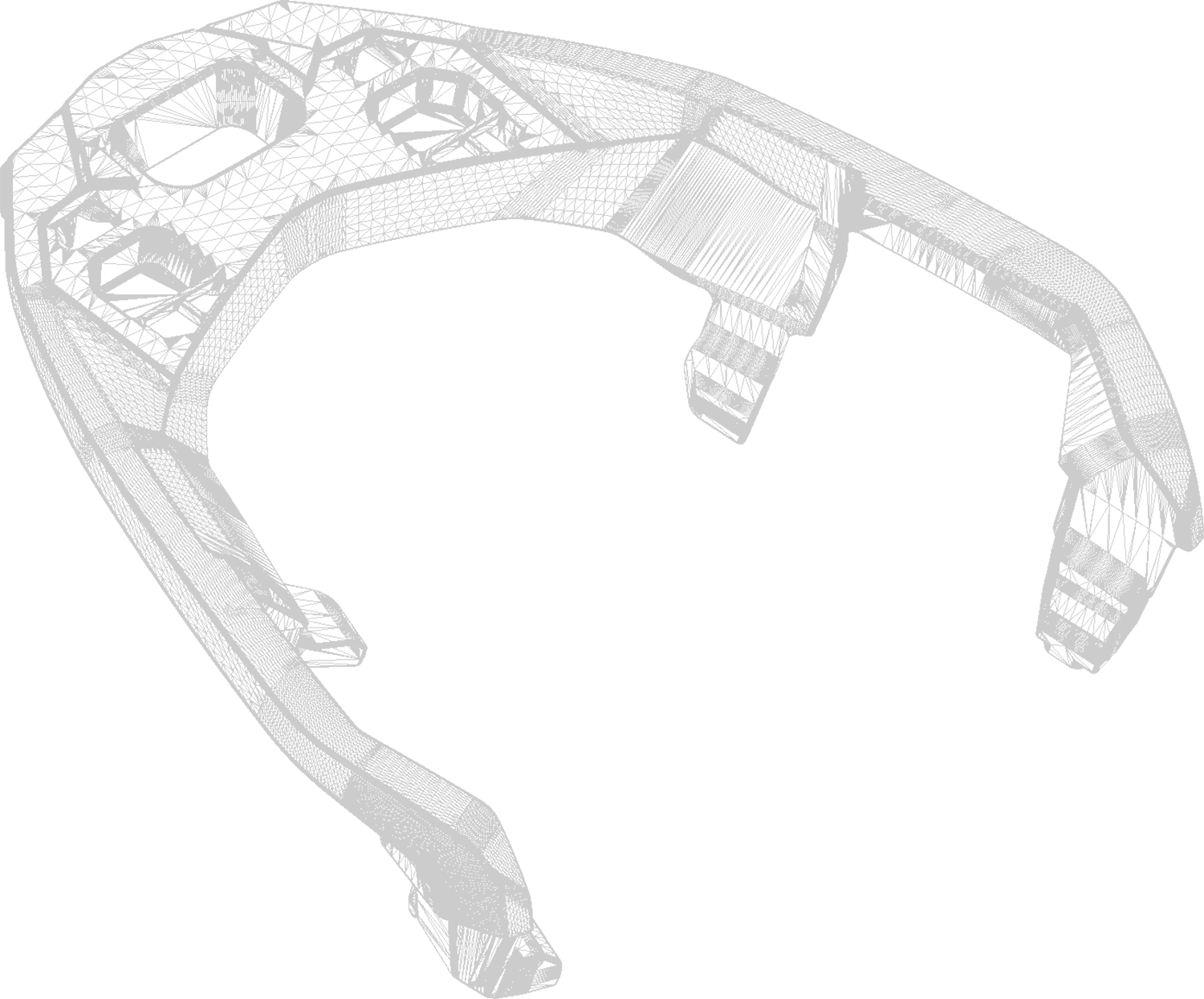

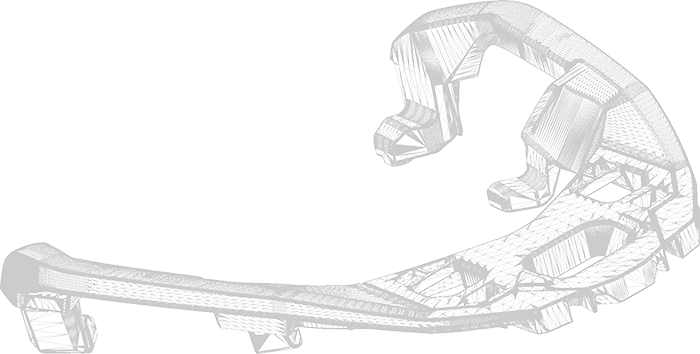

Every stage of preparation for production is carefully planned by our specialists. Feasibility studies, industrialisation, prototyping, tooling and mould production, as well as validation, are all carried out in-house by our highly skilled personnel.

Through Research & Development, we anticipate industry advancements, constantly seeking innovative solutions to meet the challenges of the future.

Quality

Technology laboratory and quality control laboratories.

Production is continuously monitored by our quality control team, which operates within six modern metrology labs, maintaining temperature and humidity conditions in accordance with ISO standards.

Manufactured products are regularly measured, with real-time data collection and processing to monitor process stability and machine performance.

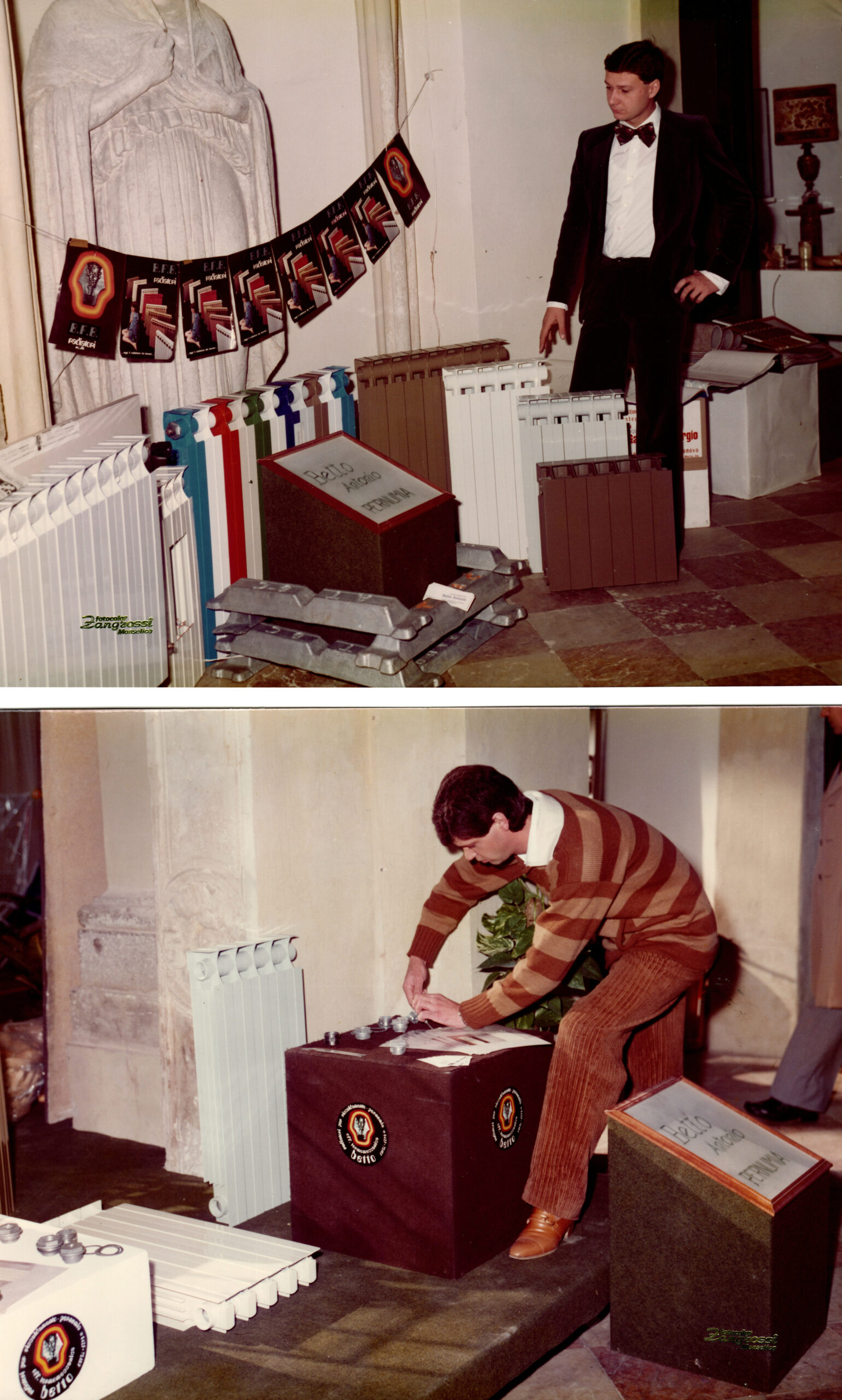

MUSEO TMB

Our Company Museum, guardian of our history and evolution.

Inaugurated in 2018, Museo TMB illustrates the story of a company that has gone from small orders to large productions for major companies in the world in the automotive and motomotive sectors. You can experience first-hand the evolution of technological processes that have characterized the manufacturing of historical products, listen to direct testimonies from our employees and see real motorcycles in which we find finished parts that have been manufactured here. You will be able to take a dip into Grimeca’s past, spacing among the most famous pieces that have made it such an established and appreciated player in the world of motorcycles. You will also be able to appreciate (and experience) the world of Alutecnos, confirmed to be highly appreciated in the big-game fishing sector by lovers of this fascinating sport. Museo TMB is located in Ceregnano (RO), via Trieste 906, and is open by reservation only for groups, schools and events.